usp compressed gas system testing|Requirements for compressed Air in the Pharmaceutical Industry : Brand manufacturer FRANK PANOFEN, PhD, is Sterility Assurance/Microbiology Product Line Manager, at Particle Measuring Systems. Dr Panofen has a Diploma in Chemistry from the University of Bielefeld and a PhD in molecular and cell biology from the University of . See more 2 dias atrás · Jewel Changi Airport has ample dining options for you to choose from. Dine in at your favourite restaurants before departing on your next flight.

{plog:ftitle_list}

WEB14 de jul. de 2022 · The live casino is – genuinely – a lot of fun to play. The entry-level stakes are also considerably lower than Las Vegas. You can also just lurk and watch the .

Validation of Compressed Air Systems

As shown in Table 2, the testing and monitoring of compressed air and other process gases, such as gaseous and liquid nitrogen, oxygen, argon, and carbon dioxide, that come into direct contact with pharmaceutical drugs during the manufacturing process is vital to assuring the quality and safety of these products. . See moreCompressed gas kits allow the microbial samplers to perform microbiological monitoring of compressed gases. Figure 1shows an example setup. This compressed gas kit . See moreAspects to consider when determining the right investment: 1. Return on investment: rare measurement vs investment 2. Multi-functional . See moreFRANK PANOFEN, PhD, is Sterility Assurance/Microbiology Product Line Manager, at Particle Measuring Systems. Dr Panofen has a Diploma in Chemistry from the University of Bielefeld and a PhD in molecular and cell biology from the University of . See more

One question users need to ask themselves is: When do I need to perform the decompression of the compressed gas? Some suppliers prefer decompression prior to sampling, and others promote sampling under compression with a . See moreFor more information on certification of designated medical gases, see the draft guidance for industry Certification Process for Designated Medical Gases. When final, this guidance will .

test tibial torsion site physio-pedia.com

The USP (the US Pharmacopoeia) handle the testing of water or oil content quite easily: the so-called mirror test is required. In this case, one lets the gas flow against a .Compressed medical gases (CMG or medical gases) include gaseous and liquid (cryogenic) forms stored in high-pressure cylinders that are administered as a gas. Types of compressed Sometimes a level of confusion arises with auditors assuming medical grade standards should be applied. This is indeed not necessary and a more considered approach is required, based on the application of the .The validation of a Compressed Air System in the pharmaceutical industry is typically performed according to the requirements and guidelines provided by regulatory authorities such as the International Society for Pharmaceutical .

With an air sampler, water vapor could affect viable particles and their ability to grow in the gas line. Testing for Non-Viable Particles Using a Particle Counter When testing a compressed gas line using a particle counter, ISO 8573-4 should be followed. The particle counterValidation of Compressed Air Systems in the Pharmaceutical Industry. The validation of a Compressed Air System in the pharmaceutical industry is typically performed according to the requirements and guidelines provided by .

Trace Analytics, LLC specializes in the analysis of thousands of compressed air & gas samples each year. Many of our customers have established their own criteria by monitoring the performance of the system over a given time period, reviewing literature/specifications, evaluating equipment parameters, and determining company objectives.Use industrial grade helium (99.99%) as the carrier gas, with a thermal-conductivity detector, and control the column temperature: the peak response produced by the assay specimen exhibits a retention time corresponding to that produced by the USP Oxygen–Helium RS, NF24 and is equivalent to not more than 1.0% of oxygen when compared to the .A 24-48 hour incubation period will then determine the presence, or otherwise, of any viable micro-organisms within the air system. d) Remaining test with gas detector tube : Compressed air, oxygen, nitrogen, and carbon dioxide are often used in pharmaceutical production environments and are subject to the Good Manufacturing Practices.Part 3: Test methods for measurement of humidity. Part 4: Test methods for solid particle content. Part 5: Test methods for oil vapor and organic solvent content. Part 6: Test methods for gaseous contaminant content. Part 7: Test method for viable microbiological contaminant content. Part 8: Test methods for solid particle content by mass .

Quantus provides compressed gas testing for Life Sciences, including oil mist and vapor analysis. Ensuring safety, compliance, and optimal performance. . Ensure the highest standards of purity and compliance in your compressed air and gas systems with Quantus. Our expert testing services are designed to meet the rigorous demands of FDA .

Specifications like USP dictate acceptable amounts of other gases present. Gas purity can be influenced or disrupted by leaks in the system, which can add ambient air to the mixture. . Pure gas testing can help users meet standards like JECFA, FCC, CGA, EU 231, NFPA 99, USP, ISO 8573 and more. . To read articles on Compressed Air and .

Pharmaceutical gas analysis, compressed air testing, oxygen purity testing, nitrogen testing, carbon dioxide testing, GMP compliance, SGS Life Science Services, pharmaceutical production, gas contamination testing, microbiological analysis, pharmacopoeia standards Created Date: 5/8/2023 9:39:55 AMMicrobial Testing of Compressed Air Micro Testing of Compressed Air or Bioburden Testing per ISO 8573-7 is generally conducted by the pharmaceutical, medical device and food industries. Microbial contaminants found in the compressor or compressed air lines can be devastating to a final product in these industries. A regular Micro Testing program can provide insight to a . Medical gas supply systems deliver CMGs to piped distribution systems at health care facilities. Oxygen USP (United States Pharmacopeia) and medical air USP provide direct assistance for breathing and also assist in the delivery of medical treatment(s). Oxygen USP, medical air USP, and CMG mixtures are used in hyperbaric chambers.

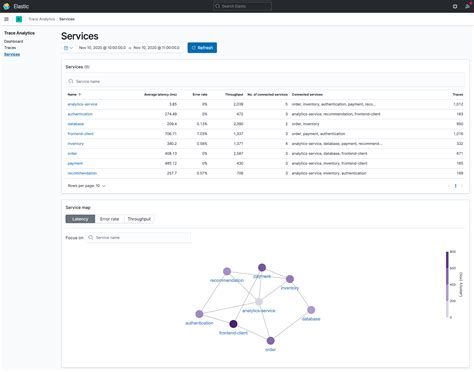

Trace Analytics

(1) Once per quarter for compressed air and nitrogen gas.- In Parenteral Dept. (2) Once per quarter for Compressed air – In Solid Dosage Area. 5.8 Sample quantity: Adjust the flow meter to 6 m3/hr & draw the sample for 10 min to sampled 1 m3 of air or nitrogen gas. 5.9 Sampling Point: Compressed Air & Nitrogen Gas in Parenteral Department.At CEGTH, we offer effective testing solutions for your compressed air systems as per the guidelines of ISO: 8573/ USP/EP/BP. Breathing Air Validation. The Compressed Gas Association sets quality standards for breathing air is GRADE D (ANSI/CGA G-7.1’97) CEGTH offers testing of breathing air quality for the following parameters:

Important Aspects of ISO 8573. ISO 8573-1 does not include purity classes for gases. ISO 8573 provides testing methods in Part 6 and specifically refers to carbon dioxide, carbon monoxide, hydrocarbons with 5 or less carbons in the chain (C 1 to 5), sulfur dioxide, nitric oxide, and nitrogen dioxide.If your product could be adversely affected by a particular gaseous .Using our A2LA Accredited Laboratory for your analytical needs assures you that our laboratory staff, test equipment and methods, quality assurance of test and calibration data have met or exceeded internationally accepted standards . Compressed air, also referred to as process gas, is used in many capacities in the pharmaceutical industry. Regular quality control testing plays an important role in the safety of your products. The ISPE Good Practice Guide .An isolator used for sterility testing is equipped with microbial retentive filters (HEPA filters are required). At rest, the isolator meets the particulate air-quality requirements for Class 100 area as defined in U.S. Federal Standard 209E (see Microbiological Evaluation of Clean Rooms and Other Controlled Environments 1116).However, the isolator need not meet Class 100 conditions .

Pure gas testing made simple with the experts at Trace Analytics. . USP Oxygen 99 Percent-2004: N/A: 10: N/A: 300: N/A: N/A: 99.0-100.0: . and modifications of compressed air and gas systems should all be validated prior to use. Air or gas system validations become even more critical in the cases of pharmaceutical or food manufacturing .TRI Air Testing pharmaceutical services for compressed air and pure gas testing includes Direct Product Contact, Indirect Product Contact, United States Pharmacopeia (USP), European Pharmacopoeia, ISO 8573, ISO 14664 compressed air standard. . ambient air and pure gas delivery systems. This includes a multitude of pure gas types up to Five 9 .

Working with a third-party accredited laboratory that specializes in compressed air and gas testing makes the process straightforward. For more information, please contact Trace Analytics via email:[email protected] or phone: 512-263-0000 ext 5. Resources: Ochoa, R. (n.d.). Sampling and testing for compressed air contaminants. Compressed .

5.3 Test for Oil and Moisture Content Note: These tests are applicable for Compressed air points only. 5.3.1 This test shall be performed by the external testing laboratory as per protocol or by using gas detector tubes (Gastec). 5.3.2 Frequency Sample Point from Compressed Air Generation System: Once a Month Compressed air and other proces gases are used in a lot of different steps during pharmaceutical manufacturing. Some examples are the use of compressed air in direct contact with products to clean, aerate, or move them through the processes or the using process gases in fluid pumps that take products through the production and filling processes. Compressed .

Common uses of compressed air The ISPE Good Practice Guide asserts that a logical method for determining the requirements of a facility’s compressed air quality is to review the role of the gas in the process. Process gases and compressed air are used in a variety of ways depending on the product manufactured. While some facilities use compressed air in .Connect the sample inlet to the compressed gas line, including any electrical control connections to the instrument. Perform a blank of the gas in test, this allows a purge cycle of gas to be tested to clear out any remaining sterilant; this test is performed without agar. Inset a test 140 mm agar plate onto the rotation platform.Start supply of nitrogen gas to the test assembly. If required adjust the flow rate by setting knob of flow meter. Record the time. On completion of 20 minutes stop supply of nitrogen gas to test assembly. Record the reading for oil content shown on the scale by pale blue color. Detach Gastec tube from the test assembly.

Requirements for compressed Air in the Pharmaceutical Industry

We qualify water systems, compressed air and gas systems, HVAC systems, autoclaves, stability chambers, incubators, refrigerators, freezers, ovens, hoods, and other equipment that has specific user requirements. . HEPA integrity, room air changes, room pressurization, and static/dynamic airflow visualization video. Additionally, we test USP .

D. Compressed Air Test Functions 1. Perform Installation Qualification. 2. Perform general operational controls verification testing. 3. Operate system throughout the range of operating design specifications or range of intended use. 4. Verify that the compressed air system is capable of supplying pressurized compressed air to all use points.

Pharmaceutical Compressed Air and Compressed

188BET é um site de apostas online que oferece o que há de melhor no futebol e outros esportes ao redor do mundo. Tenha as melhores cotas da Internet à disposição.

usp compressed gas system testing|Requirements for compressed Air in the Pharmaceutical Industry